After five turbulent days, the more than 1,500 international manufacturers say goodbye to the AMB 2018.

91,016 visitors were interested in 2018 in this offering in the centre of Europe’s leading high-tech region Stuttgart.

We had five great laser systems on site, had many interesting conversations and applications.

If you could not visit us, we offer you here our virtual tour of the fair.

With the gyrosensor of your smartphone or tablet, you can “commit” our booth! Just click on the corresponding icon in the lower left corner.

If you have a VR glasses or similar you can also use the VR function.

Have fun at our booth, we look forward to your visit!

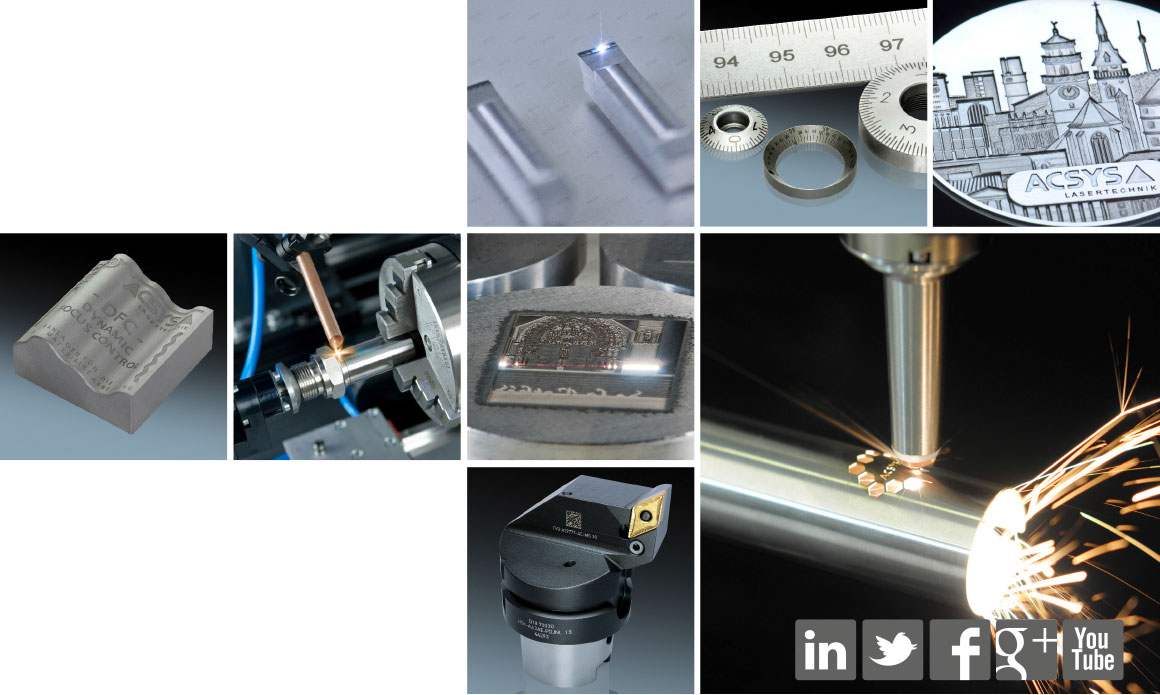

ACSYS presents the new PIRANHA Roboshift, the PIRANHA Multishift, the PIRANHA II cut, BARRACUDA Multi and the brand new PIRANHA from ACSYS with picosecond fiber laser!

The all new PIRANHA Roboshift – Flexible and dynamic pick up, processing and storing. These are the core topics of this automated laser processing system. At the heart of the laser is a compact 6-axis robot with the approximate length and reach of a human arm. This enables highly flexible process automation in many industrial sectors. Whether laser marking, laser engraving, 3D laser engraving or a combination – the PIRANHA Roboshift offers universal automation and impresses with its high throughput and short cycle times. An ideal all-rounder for a wide variety of laser processing applications.

The new PIRANHA Multi with the latest generation ultrashort pulse fiber laser offers completely new possibilities for laser material processing. The corrosion-resistant and viewing-independent black marking of stainless steel and metals is just one highlight of the new picosecond fiber laser. The “cold” machining process is made possible by the extremely short energy transfer of high intensities below the thermal relaxation time of the material – the material is vaporized abruptly.

The PIRANHA Multishift is based on the PIRANHA III. Here we have created a machine, which is a symbiosis of fully automated processing and OPR – Optical Parts Recognition. The two side loading and unloading lift stations each have a capacity of 20 trays, in which the workpieces are placed. The parts are prepositioned using a grate. The system moves one tray at a time from the loading lift station under the laser camera head.

The PIRANHA cut is an entirely new development. A compact machine for sheet metal sizes up to 600 x 600 mm², a high contour accuracy and suitable for sheet thicknesses of up to 3 mm. The cutting systems are equipped with air-cooled fiber lasers of different power ratings depending on the required application and are suitable for laser burn cutting and laser fusion cutting.

Due to its flexible layout, the BARRACUDA is the ideal basis for customized solutions. Powerful fiber lasers or diode-pumped lasers with high-speed writing heads guarantee maximum precision and minimum processing times. Multi-axis solutions extend the BARRACUDA, thereby turning it into a partially or fully automated production machine.

This laser systems fulfill ACSYS’s promise to always go a step further and do what can technically be done in an inimitable manner.

ACSYS laser systems are suitable for laser marking, laser engraving, laser cutting and laser welding. We work “live” on your workpieces and most different materials!